While I was putting the FauXplorer together in the last couple weeks, I needed to bring the nut action WAY down. I'm planning on changing it out to a Graph-Tech TUSQ-Nut, so I decided to leave the one that came on the neck for now and just deepen the nut slots for proper action. I've been using welding torch cleaners for years to tidy up nut slots. So I got them out and started. I'm not sure what this nut is made of, but the torch files just weren't cutting it (did I really say that?). I went online to see what StewMac had and went into sticker shock over the prices they ask. If I was a pro luthier, I might not mind $175 for a set of precision nut files, but when I'm only working on my own stuff and sometimes a guitar for a friend, that's a lot of cash.

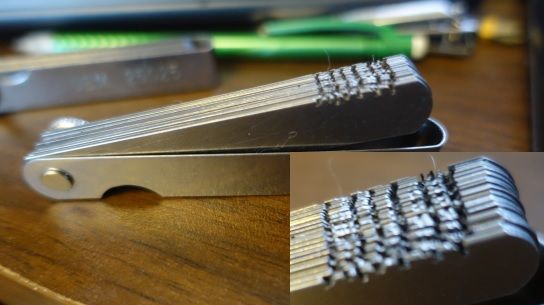

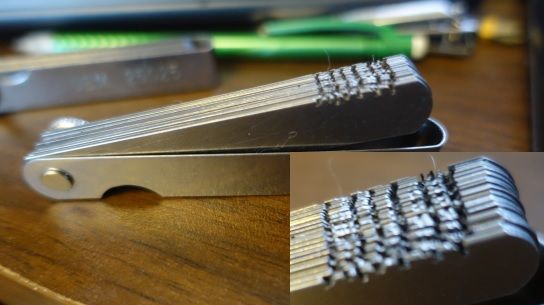

I was racking my brain trying to figure out an acceptable substitute without breaking the bank. I happened to look at the feeler gauges I use to measure nut action and neck relief and a light bulb went on. So, after a trip to the local AutoZone, I had a new set of feeler gauges, clamped them into my vise and went at them with a cutting wheel on my Dremel. They aren't pretty, but they work! These things made quick work of that nut, in fact after the amount of time I was used to filing with the welding tip cleaners, I almost overdid it on the first slot I cut in with the new "files." $7 at Auto Zone and 10 minutes of my time with the Dremel.

I was racking my brain trying to figure out an acceptable substitute without breaking the bank. I happened to look at the feeler gauges I use to measure nut action and neck relief and a light bulb went on. So, after a trip to the local AutoZone, I had a new set of feeler gauges, clamped them into my vise and went at them with a cutting wheel on my Dremel. They aren't pretty, but they work! These things made quick work of that nut, in fact after the amount of time I was used to filing with the welding tip cleaners, I almost overdid it on the first slot I cut in with the new "files." $7 at Auto Zone and 10 minutes of my time with the Dremel.